AirSep VPSA Oxygen Systems As A Replacement for Aging Cryogenic Municipal Systems

Buffalo, NY (JULY 28, 2025) – Water Quality Industry News, WEFTEC Issue

Vacuum Pressure Swing Adsorption (VPSA) oxygen systems have proven themselves to be a cost-effective alternative solution for replacing aging cryogenic municipal water and wastewater treatment systems.

AirSep, a pioneer in VPSA technology, has played a pivotal role in numerous municipal projects over its 39-year operation. However, it is essential to note that for most of these projects, it took years to reach fruition, according to James T. Klein, Jr., AirSep Regional Sales Manager – North America.

“It is just like when you have an aging furnace or water heater in your home. You review all of your options and decide what fits your budget and your long-term needs,” said Klein. “When you think of what it takes to address an aging municipal water and wastewater treatment system, it becomes significantly more complicated. You have to weigh the capital investment that taxpayers will fund. Even if the feasibility study shows savings with a VPSA system, it is still that initial investment that can take years to garner local support to move forward with this type of project.”

Klein said that once the budget is approved, the average VPSA oxygen system takes around a year from the initiation of the project to the commissioning of the plant itself.

The benefits of generating high-purity oxygen, greater than 90%, through VPSA systems not only offer cost savings in energy consumption but also provide operators with an easy-to-use, flexible system to meet their individual needs and applications requiring oxygen for the aerobic wastewater treatment method. This method utilizes oxygen to remove contaminants and pollutants, such as nitrogen and phosphorus, through biological nutrient removal (BNR). When oxygen is injected into wastewater, it stabilizes the sewage sludge and cleans the wastewater, making it odor-free and well-suited for direct discharge or water reuse.

Through VPSA, molecular sieve adsorbs nitrogen from ambient air to provide the purified oxygen generated by the system. The design of the process switching valves, adsorber vessels, and sieve fluidization protection controls provides for a long molecular sieve life in these systems.

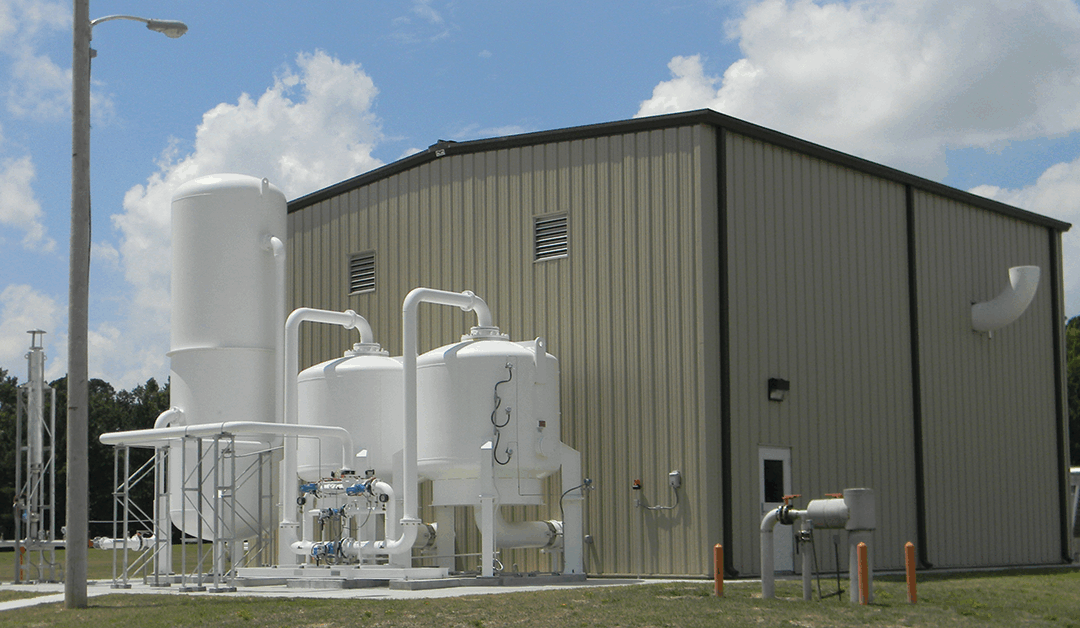

One AirSep VPSA Oxygen System in Rocky Mount, NC, installed in 2013 to treat 21 MGD, has achieved a 65 percent reduction in electricity costs thanks to this innovative technology.

This ability to “turndown” the amount of oxygen produced to 40 percent of its total capacity results in real power savings – an overall reduction in energy consumption as the oxygen system produces less. This is one of the significant differences between VPSA and cryogenic systems. Cryogenic systems offer less flexibility to customers because they consistently generate the same amount of gas and draw the same amount of power. Any wasted gas will be released into the atmosphere.

Additionally, AirSep VPSA systems can come online quickly, within 15 to 30 minutes, once installed, compared to a cryogenic plant, which can take days to reach full capacity.

AirSep offers custom-engineered VPSA oxygen systems, with capacities ranging from 2,000 SCFH (52 Nm³/hr) up to 120,000 SCFH (3,155 Nm³/hr), and has installations worldwide for a variety of applications.

In addition to VPSA Oxygen Systems, AirSep offers a comprehensive portfolio of standard Oxygen and Nitrogen PSA Gas Generators in sizes that cater to all types of requirements and applications, designed to address any gas generation challenge.

For more information, visit www.airsep.com.