VPSA O2 Tonnage Plants

- AirSep Sales & Support:

- CALL +1-716-691-0202

- Request a Call

Oxygen Products

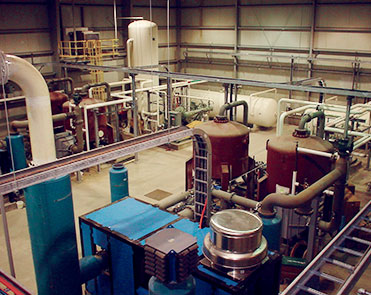

AirSep Corporation offers custom-engineered Vacuum Pressure Swing Adsorption (VPSA) Oxygen Systems.

They are designed to the specific requirements of installation, with capacities ranging from 2,000 SCFH (52 Nm³/hr) to 120,000 SCFH (3,155 Nm³/hr). AirSep’s high-efficiency, rugged 2-bed VPSA oxygen process design offers extremely low energy consumption, on stream efficiency of 99%, easy operation, and long-term equipment life of 20 years or more.

AirSep VPSA Oxygen Systems are currently in use all over the world in remote, harsh, and/or demanding environments.

AirSep VPSA Oxygen Applications & Industries Served

- Ozone Generation

- Water/Waste-Water Treatment

- Furnace Enrichment

- Steel Mills

- Gold Leaching

- Uranium Recovery

- Oxygen Bleaching and Delignification for Pulp and Paper Mills

- Oxygen Fuel Burners

- Glass Industry

WWTP Cuts Power Costs for Oxygen Generation Over 65% by Replacing Cryo Plant with VPSA System

“The new VPSA system is costing us only $345/day for electricity, compared to over $1000/day with the cryo plant. When you go with a new process, you always hope for the best. This one has not only paid off, but has done so as quickly as they promised.”

“It’s a real user-friendly system, and easy to go in and make changes.”

-Wastewater Treatment Superintendent

“Projected energy savings via the VPSA option helped to fund the project.”

“Proposals had to show benchmarks for system turndowns of 40-50%, and AirSep was able to produce that. As it turned out, they were able to perform even greater than expected in that regard.”

“The new system has freed up operators for other tasks, and I’m looking forward to seeing further savings result from that.”

“Our client is already exceptionally pleased, and has told us so in no uncertain terms.”

-Wastewater Treatment Consulting Engineer

“We custom engineer each VPSA Oxygen System to the customer’s specific requirements. For example, we do not offer capacity in standard increments only. Rocky Mount needed a 27 Tonne Plant, and we designed and supplied them with a 27 Tonne Plant.”

“After the equipment is installed and turned over to the customer, we continue to provide engineering support on an ongoing basis, at no charge to the customer, to increase their expertise and comfort level with our equipment.”

“We support VPSA plants around the world, and are able to identify the source of any operational issues in the time that it takes to receive and send an E-Mail.”

-AirSep Vice President

“What once took 20 foot long control panels with hundreds of wires and multiple control stations is replaced by a shoe box-size PLC. The high speed turbines and compressors are replaced by simple low speed blowers.”

“The entire VPSA plant is turned on or off with the touch of a button. The operator interface graphically displays real time plant operation information in a user-friendly display format.”

“The operator interface collects and stores all operating data for trending, as well as ease of trouble shooting if required. Our data collection systems operate at speeds measured in milliseconds, which allow for very precise analysis of any issue.”

-AirSep Project Engineer

Features Include

- Remote monitoring of system operation by AirSep engineers

- Critical process parameters monitored and recorded every 250 milliseconds

- Automatic turndown capability from 100% to 0% flow capacity

- Designed in accordance with local standards

- Automatic and unattended operation

- On-site start-up assistance by AirSep technicians anywhere in the world

Literature Include

- AirSep ASV Plant Layout

- AirSep ASV Plant Process & Instrumentation Diagram

- AirSep PSA/VPSA Oxygen Systems Brochure

- AirSep PSA/VPSA Oxygen Systems Brochure (Chinese)

- AirSep PSA/VPSA Oxygen Systems Brochure (French)

- AirSep PSA/VPSA Oxygen Systems Brochure (Portuguese)

- AirSep PSA/VPSA Oxygen Systems Brochure (Spanish)

- AirSep VPSA Oxygen Systems Brochure

- AirSep VPSA Oxygen Systems Brochure (Chinese)

- AirSep VPSA Oxygen System Installations

- AirSep: WWTP Cuts Power Costs Over 65% by Replacing Cryo Plant with Custom VPSA Oxygen System