Buffalo, NY (JULY 28, 2025) – Water Quality Industry News, WEFTEC Issue

Success often begins with a clear vision and the right partnerships. For over 39 years, AirSep Corporation—a CAIRE Inc. company—has thrived by collaborating with top-tier distributors, leveraging their combined expertise to drive innovation in gas generation and sustainability solutions. Together, they’ve developed technologies that not only address real-world challenges but also minimize environmental impact.

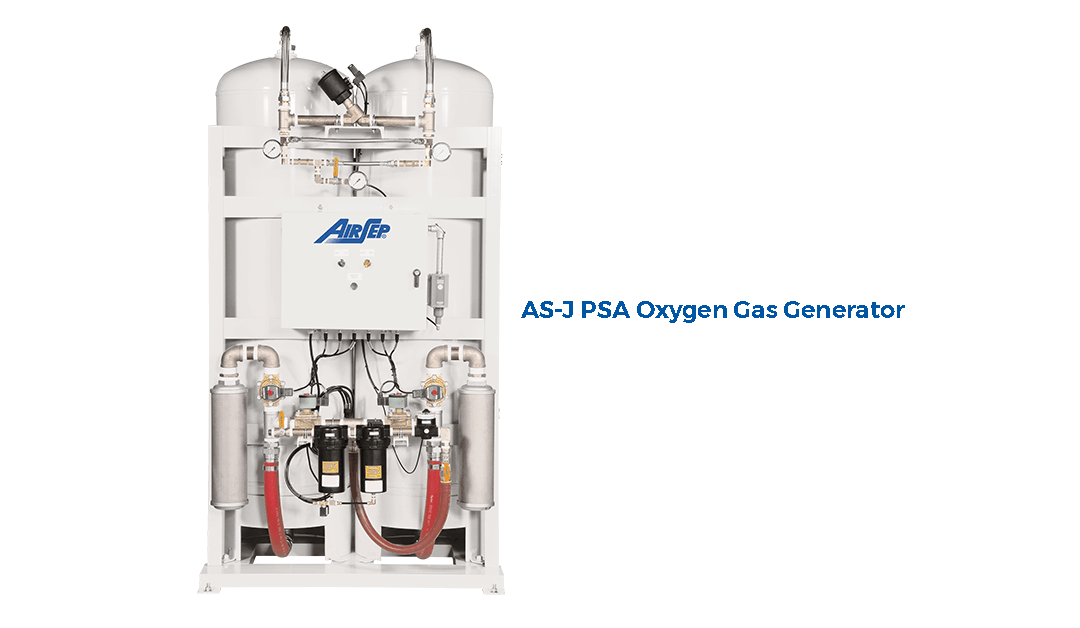

One such project involved collaboration with IER Environmental Services (Gener-Ox Systems), a company that developed the chemical-free odor control system in wastewater transport called Gener-Ox, a unique super-oxygenation technology powered by AirSep’s AS-J Pressure Swing Adsorption (PSA) Oxygen Gas Generator.

AirSep/IER Gener-Ox System

Joseph “Joe” Hennessy, AirSep Account Manager, describes the project that aimed to develop a sustainable method for treating wastewater and alleviating “rotten egg” odor complaints from local citizens.

“Sulfide issues were causing hydrogen sulfide gases to escape through neighborhoods’ lift stations, air release valves, and manhole covers, prompting many residents to file complaints about the smell with the city. Using AirSep’s innovative gas generation and adding Gener-Ox, a chemical-free technology, enabled the company to control odor and corrosion in wastewater transport without the investment in expensive chemicals, like nitrate-based products,” he said.

The chemical-free solution of using PSA oxygen is designed to prevent sewer line odor and corrosion by converting anaerobic conditions in force mains into aerobic environments.

Oxygen is used to preserve aerobic conditions throughout the force main. The oxygen is introduced into the wastewater stream, converting anaerobic conditions (where odors and corrosion occur) to aerobic conditions (characterized by the absence of odors and corrosion). Many wastewater plants throughout the Pacific Northwest in the USA utilize this technology and application.

AirSep’s broad portfolio of PSA Oxygen Gas Generators allowed IER to select the right size system from the AS series for the project. The AS series can serve anything from 100 gallons per minute (GPM) and higher wastewater flows, depending upon the customer’s needs.

Beyond PSA oxygen generation, AirSep also offers the new N2WAVE PSA Nitrogen Gas Generators and Vacuum Pressure Swing Adsorption (VPSA) systems custom-built to meet each customer’s unique requirements. With AirSep gas generation systems, users gain the convenience and efficiency of producing oxygen or nitrogen on demand, directly onsite, eliminating the need for costly bulk tank deliveries and refills.

To learn more about AirSep, visit www.airsep.com.