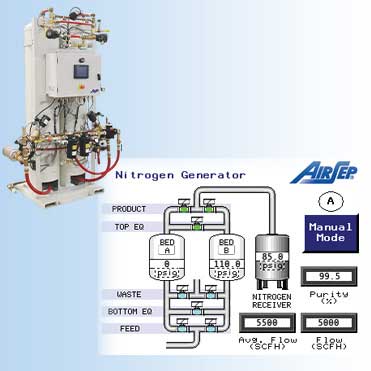

Standard Nitrogen Generators

AirSep Alpha Series Nitrogen Generators produce from 437 to 44,671 cubic feet of nitrogen per hour at 99.5% nitrogen concentration.

- To talk to an oxygen advisor:

- CALL +1-877-704-0878

- Request a Call

- email: caireconsumer@caireinc.com

Key Features + Benefits

AirSep Nitrogen Generators eliminate the expense, inconvenience, hazardous handling, and storage problems often associated with purchased liquid or high pressure cylinder nitrogen. The standard models AirSep offers are the most efficient and reliable generators available today. With their proprietary mufflers, these units also achieve the lowest sound levels in the industry.

Fully automatic, the generators require no specialized operating personnel. Simply connect an air compressor or central air supply to the generator and your application or nitrogen distribution system to the generator’s nitrogen receiver. Then connect the power cord to a grounded electrical outlet, turn the unit on, and set your nitrogen delivery pressure. A simple on-off switch supplies nitrogen whenever you need it.

AirSep PSA Control Systems

AirSep Standard Nitrogen Generator models are equipped with a NEMA 4 HMI touchscreen control panel with an integrated nitrogen transmitter. The touchscreen provides a normal start-up system, monitors/controls the operation of the process valves, monitors signals coming from the pressure transducers, and provides an alarm system, as well as a fail-safe shutdown mode. This control panel also features diagnostic capabilities and Ethernet access for remote monitoring of process parameters. The various color screens are easy to follow as the user-friendly interface maintains a consistent template design.

For any inquires or questions regarding AirSep oxygen or nitrogen equipment, please contact us at info@airsep.com and a representative will follow-up with you as soon as possible.

Key Features + Benefits

Manufacturing

- Cutting/Brazing/Soldering

- Heat Treatment

- High Pressure Plastic Injection Molding

Oil & Gas/Power Generation

- Onshore/Offshore Exploration

- Mechanical Gas Seal Inerting

- Enhanced Oil Recovery (EOR)

Food & Beverage

- Modified Atmosphere Packaging (MAP)

- Nitrogen CO2 Gas Mix Beer Drafting

- Controlled Atmosphere (CA)/Fruit Storage

- Wine Bottle Capping

Automotive

- Tire Inflation

Mining

- Control of Lower Explosive Limits (LEL)